The Working Process of Zinc Die Casting

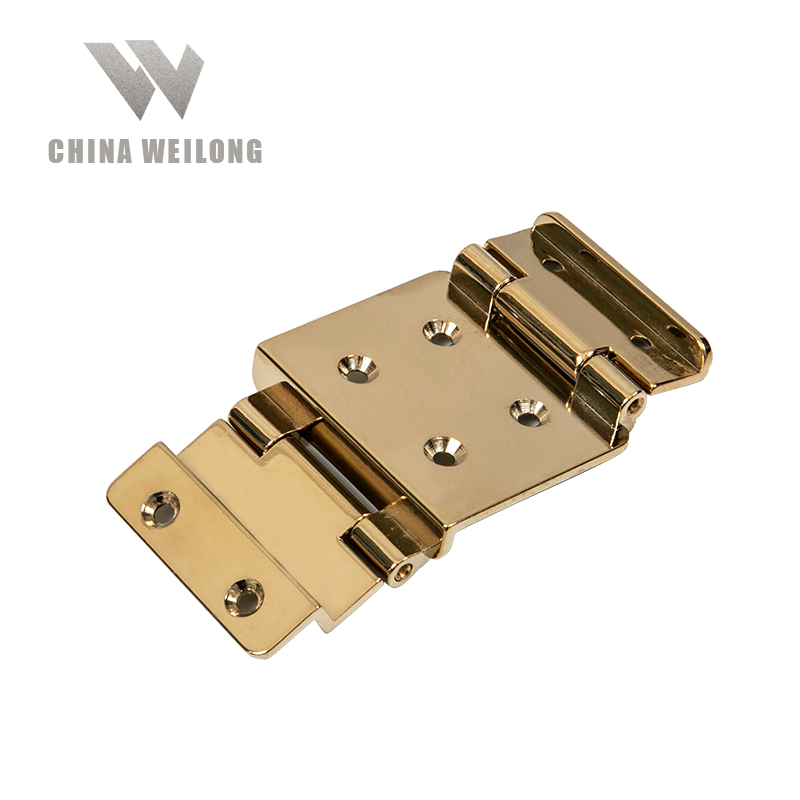

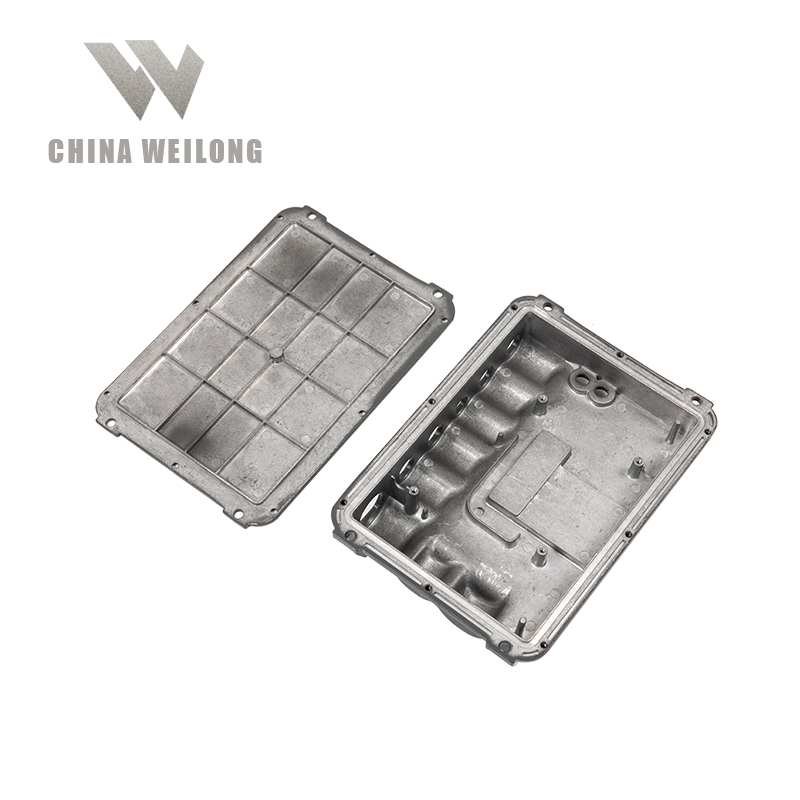

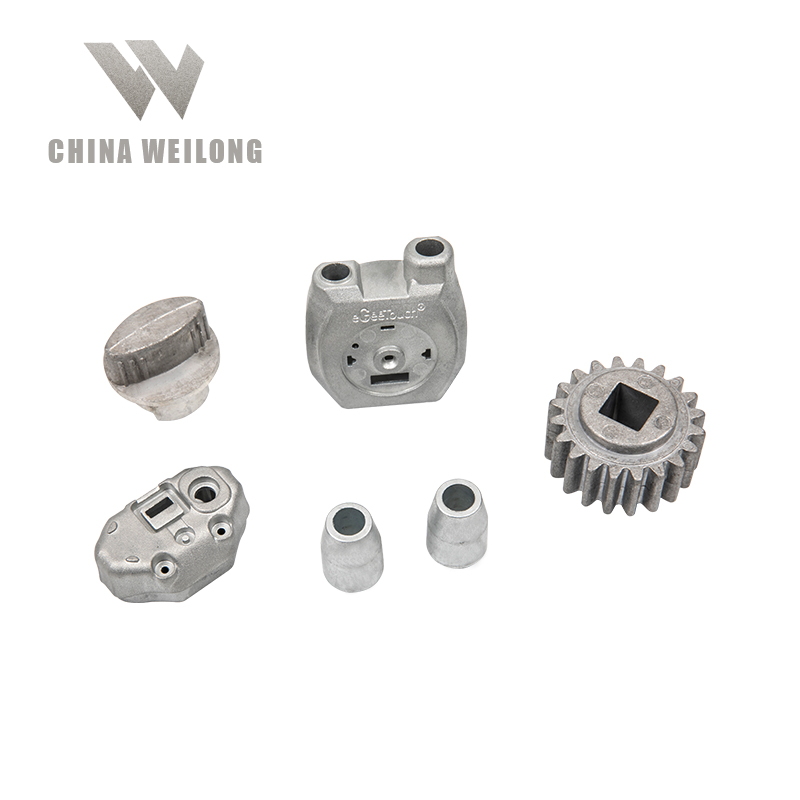

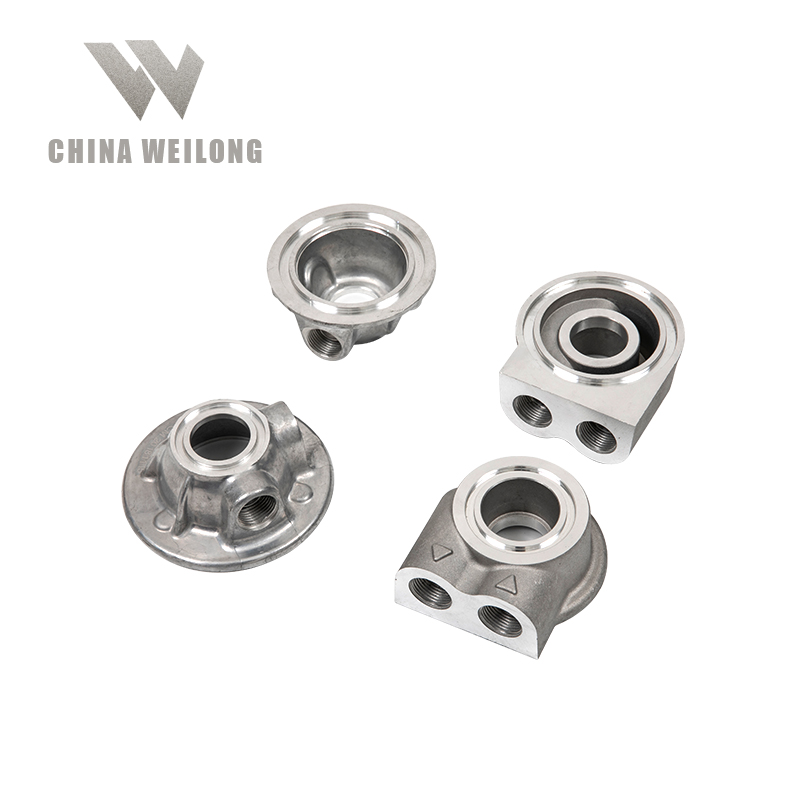

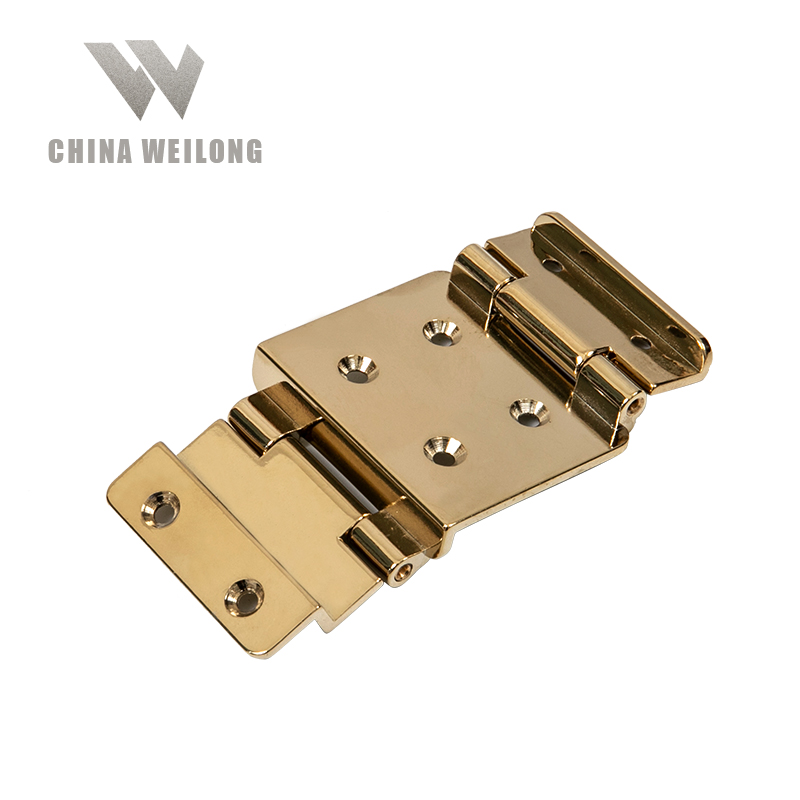

Zinc Die Casting is a kind of die casting part. It uses a die-casting machine with a die-casting die to pour the heated liquid zinc or zinc alloy into the inlet of the die-casting machine and then die-casting by the die-casting machine to cast out th...