When you're in the process of designing an aluminum part, it's essential to consider which manufacturing process you'll use to produce it. There are colorful styles for forming aluminum, and Aluminum Die Casting is one of the most common options for contrivers to consider. Aluminum die casting is the system of choice for numerous automotive, artificial, and telecommunications products. It’s also frequently used to produce electrical, hydraulic, and lighting factors.

Still, you're in the right place, If you would like to know further about the aluminum die casting process and would like some help deciding if it's the right choice for your operation.

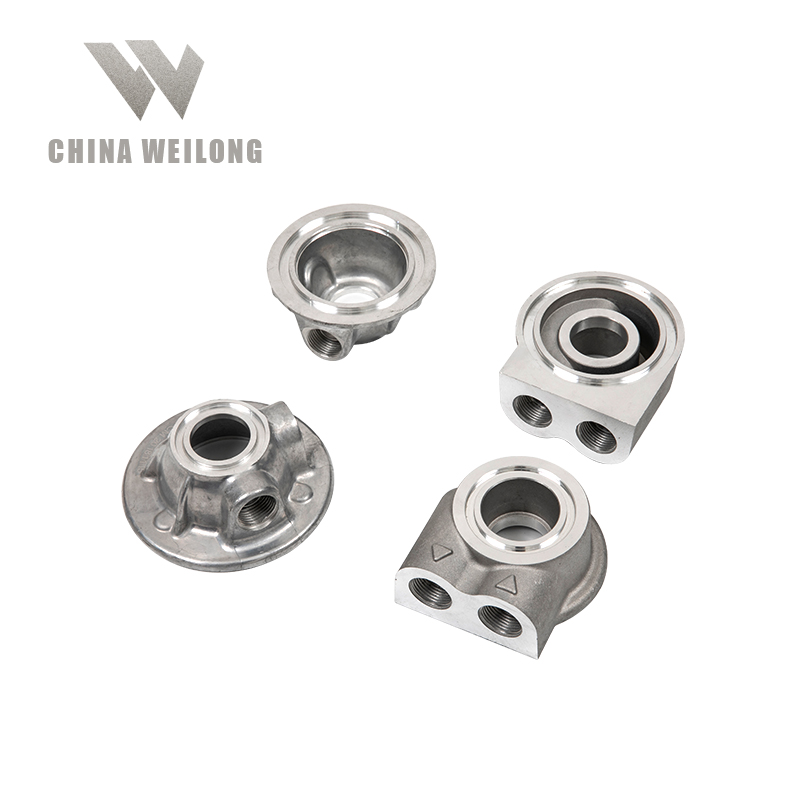

Aluminum die casting is an essence-forming process that allows for the creation of complex aluminum corridor. Beams of aluminum amalgamation are hotted to veritably high temperatures until they're entirely molten. The liquid aluminum is fitted under high pressure into the depression of a sword die, also known as an earth. The bones are made up of two halves, and after the molten aluminum has solidified, they're separated to reveal the cast aluminum part.

The performing aluminum product is precisely formed with a smooth face and frequently requires minimum or no machining processes. Given that sword dies are used, the process can be repeated numerous times using the same earth before it deteriorates, making aluminum die casting ideal for the high-volume product of aluminum corridor.

Die-cast aluminum corridor frequently bear minimum machining, and several options are available for face finishing. Die casting has a veritably good face finish by casting norms, but can still have defects, like essence seams where the earth halves meet. A rough face or other defects shy for the part can be addressed by grinding, sandblasting, or orbital sanding.